NAER KAORUI HARDWARE PLASTIC MONDEL CO.,LTD is located in Dongguan, an important manufacturing city and industrial hub in China. we have always been providing our clients reliable and quality services since 2018.

We specializes in maching various precision maching parts,can be customized according to customers’ drawings or samples.OEM/ODM is welcomed !

Our company has advanced manufacturing and inspection equipment, such as CNC large gantry machining centers, CNC machining centers, precision CNC milling machines, CNC lathes, Large surface grinders, precision straighteners, CMM,electronic altimeters.

Our company has more thaQn 10 years of precision machining experience, we produce and deliver high-quality precision parts, fixtures, test instruments and automation system to our world-wide customers in multiple industries, including Automation,Medical, Electronics, Military, Oil (petroleum), new energy vehicles, etc.

Relying on ISO2009:2015quality management system, product processing accuracy can be controlled within ±0.002MM, surface roughness (√) control in Ra0.4. no MOQ(minimum quantity),you can send us the drawing in PDF file, CAD file, or AI file),depend on the product quantity, we can check the price to you within 6 hour.you can send us the address of consignee,we can check the express cost and shipping fee for your reference too.

5 Axis CNC Machining CNC Milling / CNC Turning

Milling / Turning grinding

Heat treatment Surface treatment

2008

Founded in

Ra 0.4

Control in

10 years

Machining experience

±0.002 mm

Accuracy can be controlled within

Our is a professional precision machine parts processing company with more than 10 years of processing experience. It has a professional core team and advanced equipment and has passed the ISO9001:2015 certification. Our has introduced ERP system that tracks entire process of our components from product arrangement to shipment such as raw materials, production capacity—and the status of business commitments: orders, purchase orders,status of production and shipment.

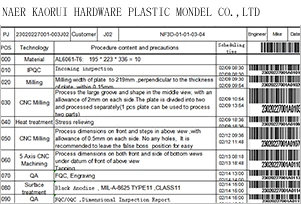

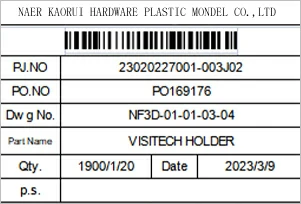

Our has an experienced engineering team to carefully review the incoming drawings as well as communicate with customers if there is any problem, and then formulate the best process flow for each part, ,input the ERP system to generate an electronic form. Ensure to provide customers with qualified products under the strict control of each process. Such as:

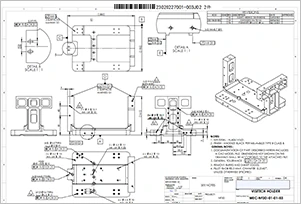

DRAWING REVIEW

PROCESS CARD

SHIPPING LABEL

Our team keeps improving and continuously optimizes the production process , use precision machine such as Five-axis Machine (DMG), CNC Milling, CNC Turning, WEDM-LS, EDM, Grinder, Milling, Turning, Grinding, etc from Germany, Japan,American, to manufacture components and improve the quality stability as well as production efficiency of the production ,The processing accuracy of the product can be controlled at ±0.002MM, and the surface coarse grain size (√) can be controlled at Ra0.2.

workshop

workshop

workshop

Quality Control Room

Our has passed ISO2009:2015 certification and complies with the ISO quality control system, strictly controls the quality and reduces defective products in each production process, so as to improve production efficiency and reduce processing costs, finally provide customers with reliable and competitive products s price. Our has also introduced various testing tools to improve the quality stability such as CMM、HeightGauge、Material Analyzer、Hardness Tester、 Glossmeter、Micromete.,etc.

Each parts is processed according to the process card and under strict quality supervision. Each process will be scanned and entered into the system in time to ensure delivery on schedule.For customer complaints, Our always communicates with customers in time and gives feedback within 12 hours.

01询价

02图纸审查

03报价单

04谈判

05生产检验

06包装

07航运

08售后服务

After ten years of development, Our not only has a large number of professional and technical personnel and excellent management team, but also has a very excellent sales team. In order to let more customers know us, we regularly go to the world to participate in exhibitions, such as: the United States, the United Kingdom, Germany, Japan and so on. We got to know a large number of customers from the exhibition, at the same time, many foreign customers came to visit our factory and discuss cooperation matters. Your support is the greatest encouragement to us. We also hope to provide high-quality machining services for more customers in need. We sincerely invite you to cooperate and develop together.

Hardware Exhibition

Hardware Exhibition

Hardware Exhibition

Hardware Exhibition

Our shares some processing cases, all of which are machined according to customers’ drawings. The processing machine involves 5 Axis CNC Machining / CNC Milling/CNC Turning/Heat treatment /Surface treatment and other processes. The processing accuracy can be controlled at ±0.002MM and surface roughness (√) is controlled at Ra0.2. K-TEK has a strong processing capacity and strict quality control system. Please freely to reach us out.

CUSTOMER SAMPLE

CUSTOMER SAMPLE

CUSTOMER SAMPLE

CUSTOMER SAMPLE

CUSTOMER SAMPLE

Our provides precision milling and turning parts services, providing professional machining services at competitive prices and timely delivery. With our strong machining capacity, the production of precision parts can meet the requirements of various equipment parts, products cover a variety of mechanical equipment, automation equipment, fixture and other industries.